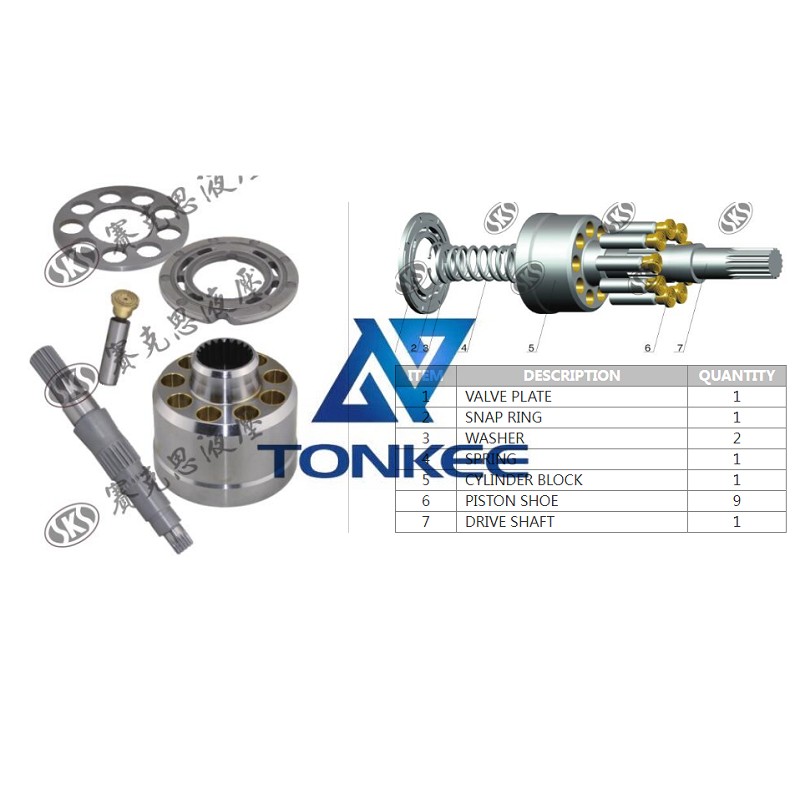

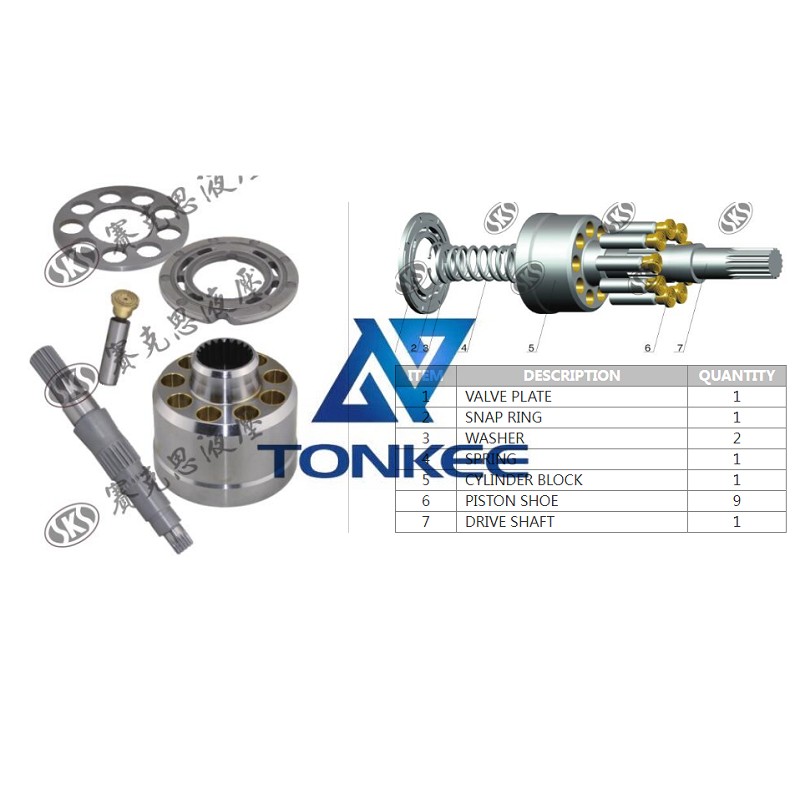

The BPV35 Valve Plate is specifically designed to regulate the flow of hydraulic fluid within a pump, ensuring efficient and reliable operation.

It is constructed using high-quality materials to withstand the demanding conditions of hydraulic systems, such as high pressures and constant movement. The valve plate is precision-engineered to provide optimal performance and durability.

One of the key features of the BPV35 Valve Plate is its ability to control the direction of fluid flow. It consists of a series of carefully designed channels and ports that direct the flow of hydraulic fluid within the pump. These channels and ports allow the fluid to enter and exit different sections of the pump, enabling the pump to generate the necessary pressure to operate hydraulic machinery.

The valve plate is also responsible for regulating the flow rate of the hydraulic fluid. It achieves this through a combination of ports and control mechanisms. By adjusting the size and position of these ports, the valve plate can modulate the flow rate according to the requirements of the hydraulic system. This control ensures that the pump delivers the precise amount of hydraulic fluid needed for optimal performance.

Another important function of the BPV35 Valve Plate is to control the pressure within the hydraulic system.

It achieves this through a system of relief valves and pressure differentials. When the pressure within the system exceeds a predetermined level, the relief valves in the valve plate open, allowing excess fluid to bypass the pump and return to the reservoir. This prevents damage to the pump and other components and maintains the desired pressure range.

The BPV35 Valve Plate is designed to be compatible with a wide range of hydraulic pump models, making it a versatile choice for various applications. It is engineered to meet industry standards and undergoes rigorous quality control checks to ensure consistent performance and reliability.

Installation and maintenance of the BPV35 Valve Plate are relatively straightforward. It can be easily fitted into the hydraulic pump assembly, and regular inspections and cleaning can help extend its lifespan. However, it is crucial to follow the manufacturer's guidelines and recommendations for proper installation, maintenance, and replacement to ensure optimal performance and safety.

English

English Türkçe

Türkçe