The FG95 swash plate hydraulic pump is known for its robust construction and high-performance capabilities.

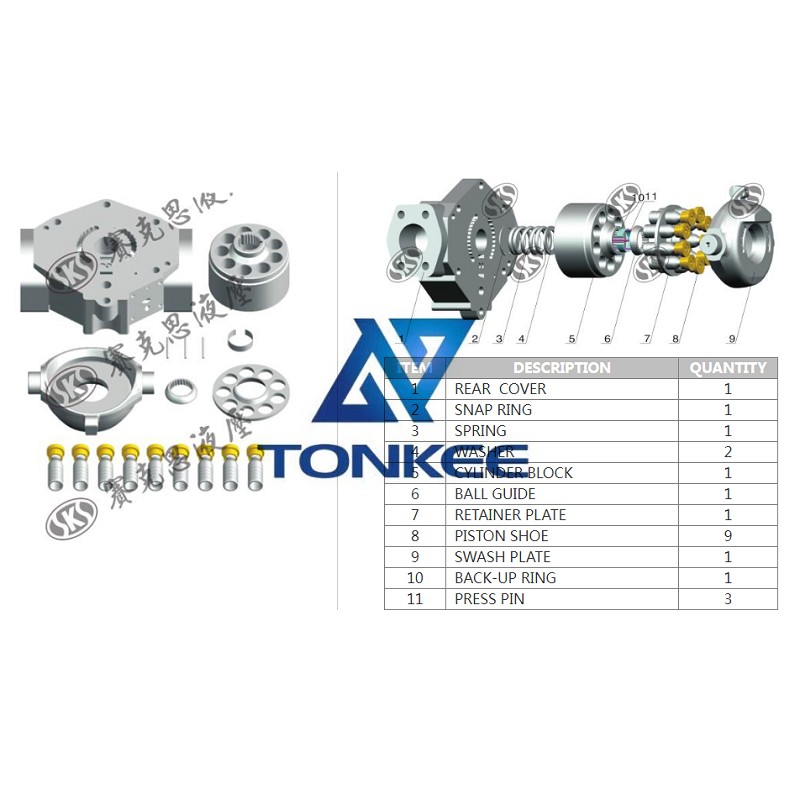

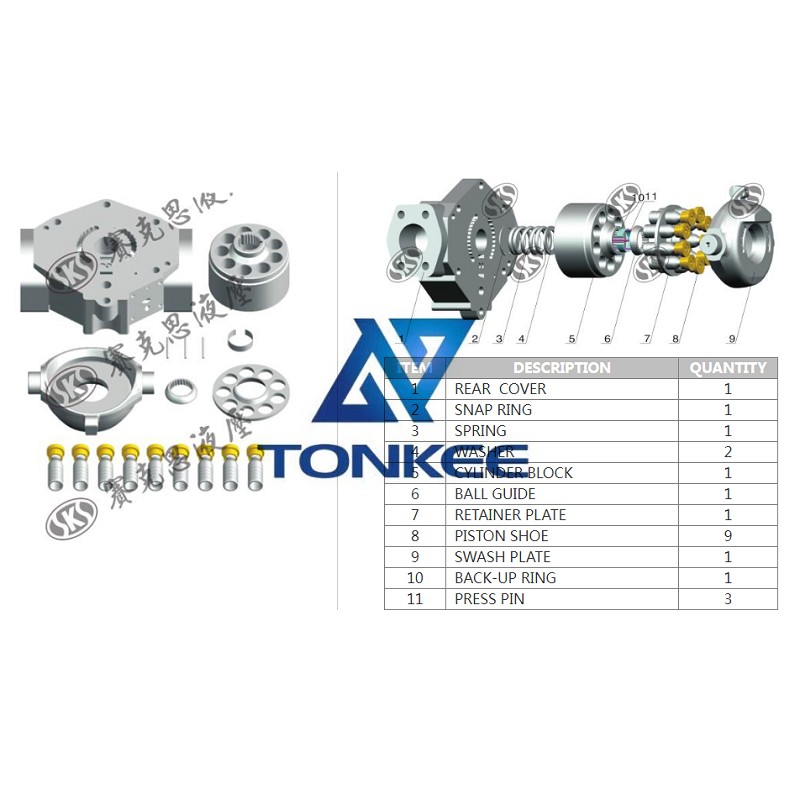

It is designed to withstand rigorous operating conditions, making it suitable for use in demanding industrial applications. The pump consists of several key components, including a swash plate, pistons, cylinder block, and valve plate.

The swash plate is a critical element in the pump's operation. It is connected to the drive shaft and rotates at a specific angle. As the swash plate rotates, it creates an axial movement of the pistons, which are housed in the cylinder block. This movement generates pressure differentials, causing the hydraulic fluid to be drawn into the pump and subsequently discharged at a higher pressure.

One of the notable features of the FG95 swash plate hydraulic pump is its variable displacement capability. This means that the pump can adjust its output flow to meet the specific requirements of the hydraulic system. By altering the angle of the swash plate, the pump can regulate the volume of fluid being delivered, providing precise control over the hydraulic system's operation. This feature is particularly beneficial in applications that require varying flow rates or load conditions.

Another important aspect of the FG95 swash plate hydraulic pump is its efficiency.

The pump is designed to minimize energy loss and maximize overall system performance. It incorporates advanced technologies and materials to reduce friction and internal leakage, resulting in improved efficiency and reduced operating costs. The high-quality components and precise manufacturing ensure reliable and consistent performance over extended periods.

The FG95 swash plate hydraulic pump finds application in various industries, including construction, agriculture, manufacturing, and material handling. It is commonly used in hydraulic excavators, loaders, cranes, and other heavy machinery. Its versatility and adaptability make it suitable for both mobile and stationary hydraulic systems.

English

English Türkçe

Türkçe