Flow Rate: The flow rate, measured in gallons per minute (GPM) or liters per minute (LPM), indicates the volume of fluid that the pump can deliver per unit of time.

The flow rate requirement depends on the hydraulic system's demands and the actuators it powers.

Pressure Rating: The pressure rating determines the maximum pressure that the pump can generate to provide sufficient force for the hydraulic system. It is typically measured in pounds per square inch (PSI) or bars.

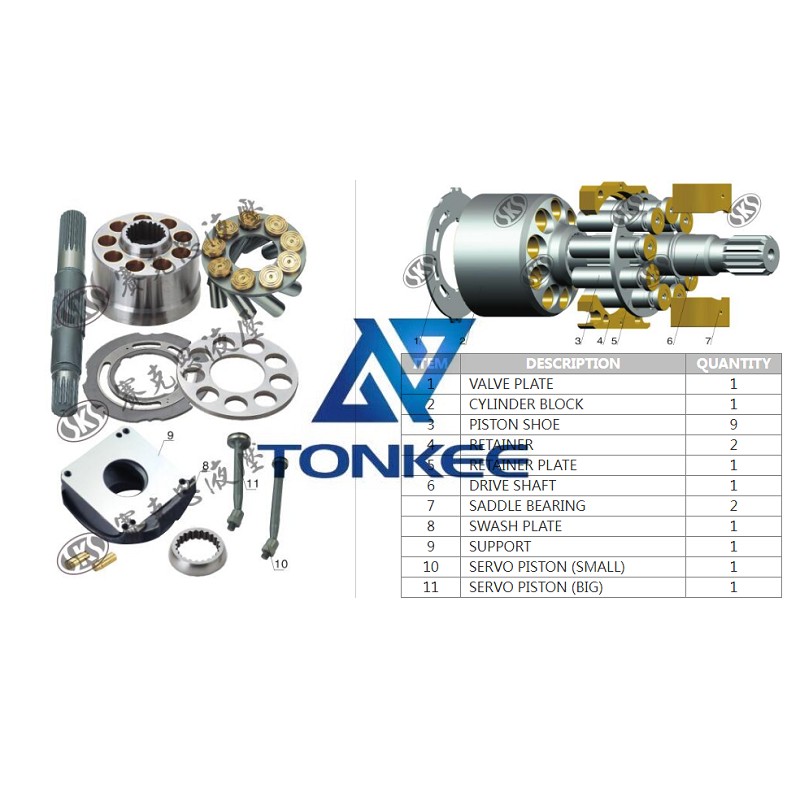

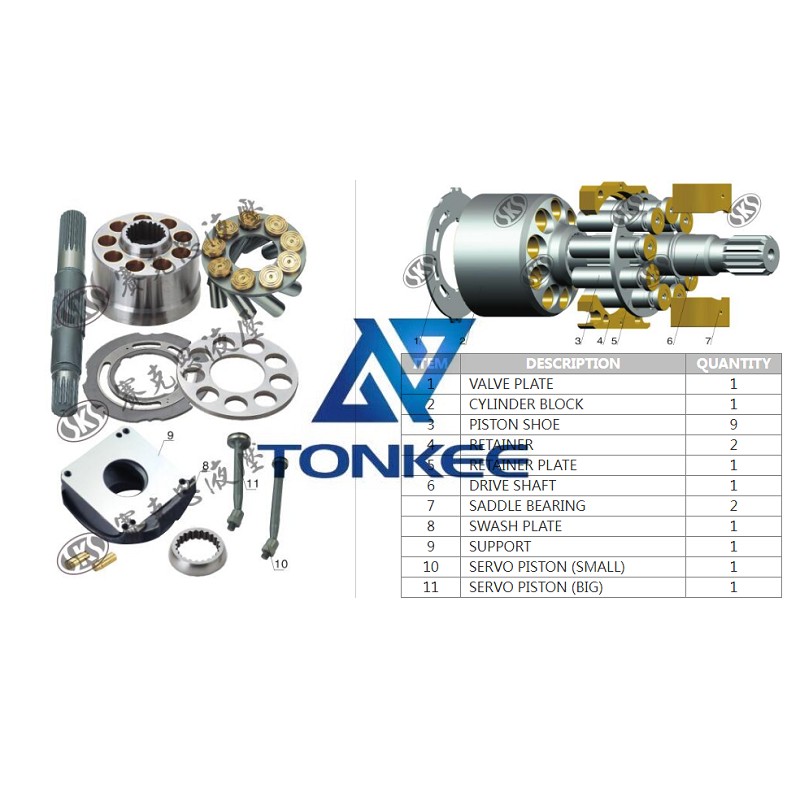

Pump Type: There are different types of hydraulic pumps, including gear pumps, vane pumps, piston pumps, and axial piston pumps. Each type has its advantages and is suitable for specific applications based on factors such as pressure requirements, flow rate, and efficiency.

Efficiency: Pump efficiency is an important consideration to minimize energy loss and optimize overall system performance. Higher efficiency pumps can reduce energy consumption and improve the system's overall efficiency.

Mounting Configuration: Hydraulic pumps can have various mounting configurations, such as flange, foot, or inline mounting.

The mounting configuration determines how the pump can be attached to the power source or other system components.

Physical Size and Weight: The physical dimensions and weight of the hydraulic pump are crucial for integration into the equipment or machinery. It is important to ensure that the pump fits within the available space and meets any weight restrictions.

Fluid Compatibility: The hydraulic pump must be compatible with the hydraulic fluid used in the system. Different pumps may have specific requirements for the type and viscosity of the fluid to ensure proper lubrication and prevent damage to internal components.

Noise Level: Some applications require low noise operation. It's important to consider the noise level generated by the hydraulic pump, especially in noise-sensitive environments.

English

English Türkçe

Türkçe