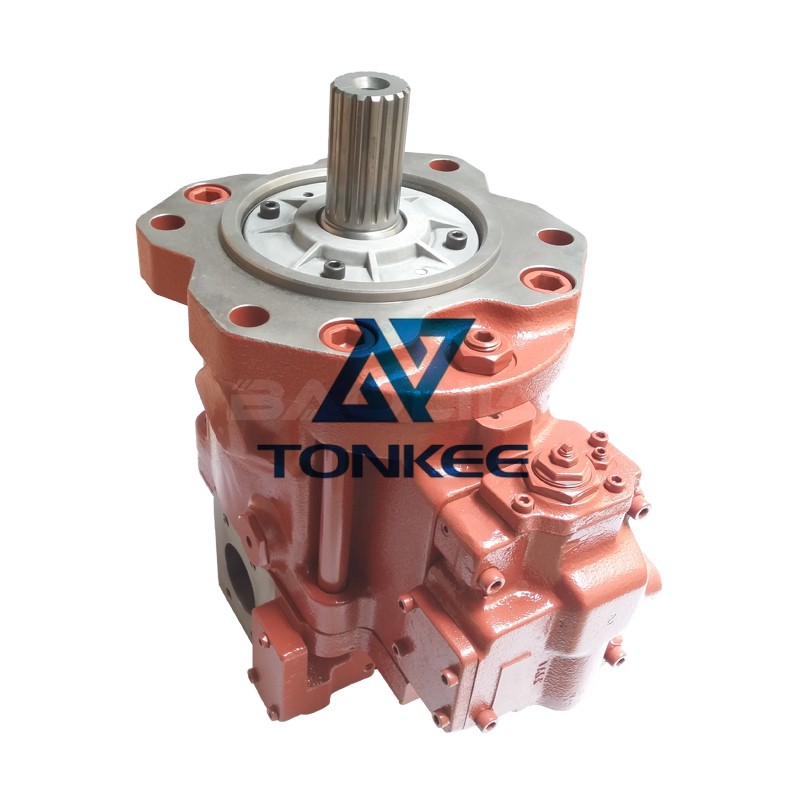

The K3VG series pump is known for its exceptional power density, providing high-pressure capabilities with compact size and weight.

This feature makes it ideal for applications where space is limited but demanding hydraulic power is required. The pump utilizes a swash plate design that allows for variable displacement, enabling the adjustment of fluid flow according to system requirements. This flexibility enhances its versatility, making it suitable for a wide range of hydraulic machinery.

One of the notable improvements in the new specification of the Kawasaki K3VG series hydraulic pump is its enhanced efficiency. The pump incorporates advanced hydraulic technologies and precise engineering to minimize internal leakage and maximize energy conversion. As a result, it offers improved overall efficiency, reducing energy consumption and optimizing system performance. This efficiency improvement not only reduces operational costs but also contributes to a greener and more sustainable operation.

Another significant aspect of the new specification is the pump's increased durability and reliability. Kawasaki has employed innovative materials and advanced manufacturing techniques to enhance the pump's resistance to wear, corrosion, and high-pressure conditions. This ensures a longer service life and minimizes maintenance requirements, leading to increased uptime and productivity for the machinery in which the pump is installed.

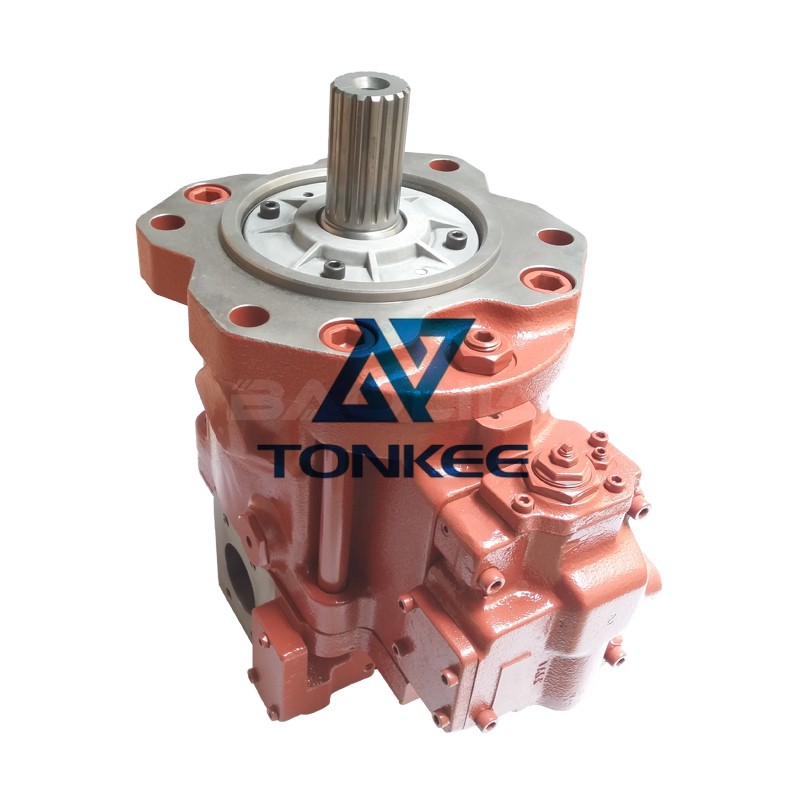

Furthermore, the K3VG series hydraulic pump incorporates advanced control options to optimize its performance and adapt to different operating conditions.

It features a comprehensive range of control mechanisms, including electro-hydraulic proportional control, electronic displacement control, and load-sensing control. These control options enable precise and efficient operation, allowing for smooth and responsive hydraulic power delivery, regardless of the application's demands.

The new specification of the Kawasaki K3VG series hydraulic pump also focuses on improved noise and vibration reduction. Kawasaki has implemented advanced noise suppression technologies, such as optimized internal component design and vibration isolation, to minimize the pump's noise emissions. This feature is particularly important in applications where noise reduction is crucial for operator comfort or compliance with noise regulations.

English

English Türkçe

Türkçe