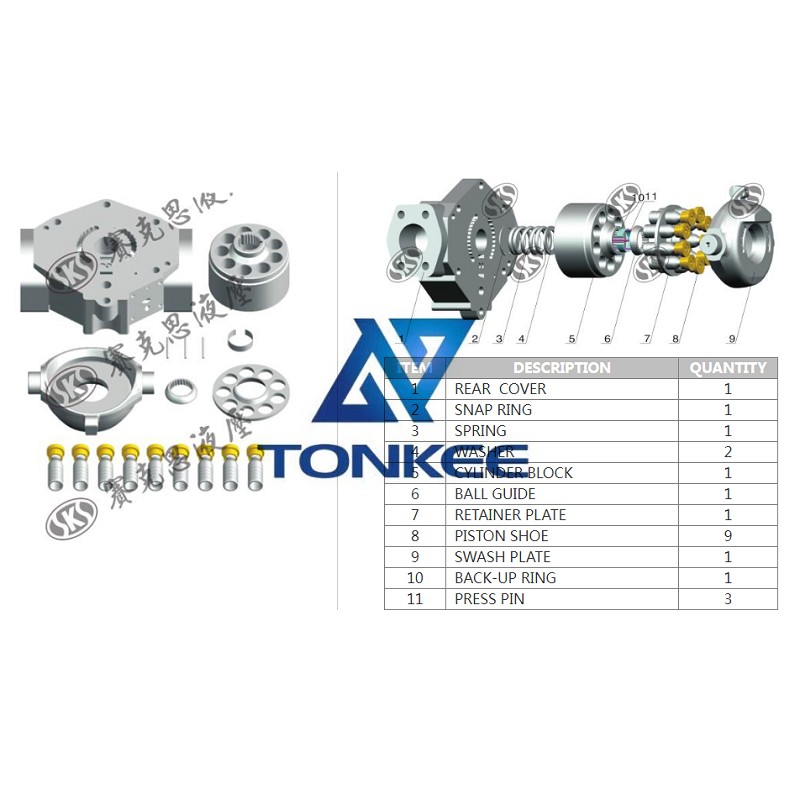

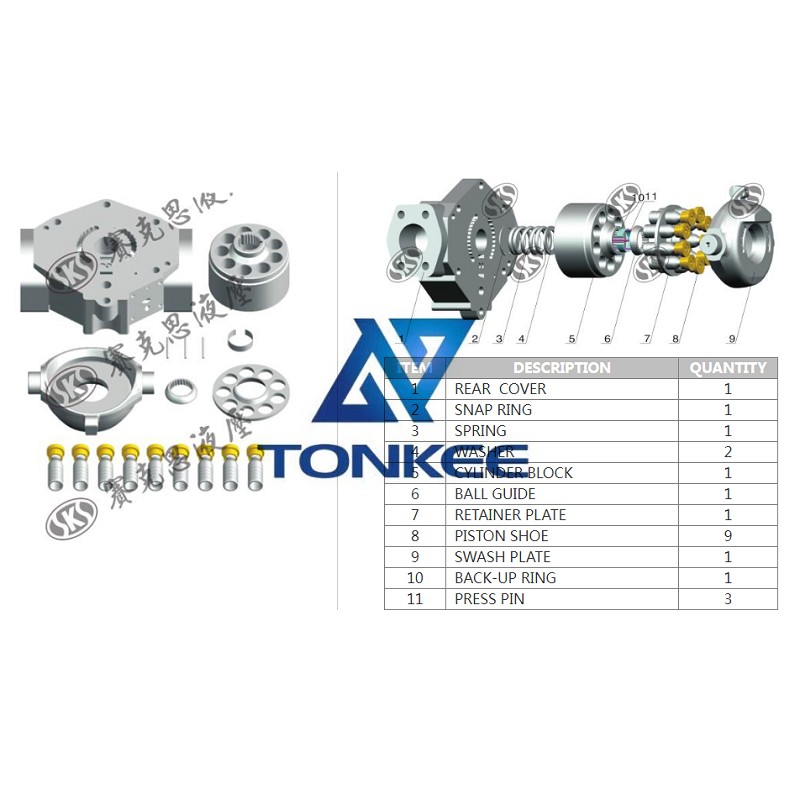

The primary function of the FG85 Back-Up Ring is to support and enhance the sealing capabilities of the primary sealing element, such as O-rings or hydraulic seals.

It is typically installed on the non-pressurized side of the sealing system, acting as a mechanical barrier to prevent extrusion and maintain the integrity of the seal.

One of the key features of the FG85 Back-Up Ring is its construction. It is made from a variety of premium materials, including high-grade elastomers or thermoplastics, selected for their excellent resistance to pressure, temperature, and various hydraulic fluids. These materials ensure the back-up ring can withstand demanding operating conditions and maintain its sealing effectiveness over an extended period.

The design of the FG85 Back-Up Ring is meticulously engineered to provide optimal performance. It features a precise geometry and dimensions that enable it to fit securely within the hydraulic pump assembly. The back-up ring is designed to exert a controlled amount of radial force against the primary seal, helping to maintain its position and prevent extrusion under pressure. This design ensures a reliable and long-lasting seal, even in high-pressure hydraulic systems.

Furthermore, the FG85 Back-Up Ring is manufactured to strict quality standards, ensuring consistency and reliability across each unit produced.

Partsdic® employs advanced manufacturing processes and rigorous quality control measures to deliver products that meet or exceed industry standards. This commitment to quality ensures that the FG85 Back-Up Ring performs flawlessly in hydraulic pump applications, reducing the risk of leaks, downtime, and costly repairs.

The installation and maintenance of the FG85 Back-Up Ring are straightforward. It can be easily installed in hydraulic pump systems using standard tools and techniques. Regular inspection and replacement of the back-up ring, along with other sealing components, are recommended to maintain optimal performance and prevent potential system failures.

English

English Türkçe

Türkçe