The thrust plate pump operates on the principle of positive displacement, where a rotating assembly generates a pumping action by trapping and displacing hydraulic fluid.

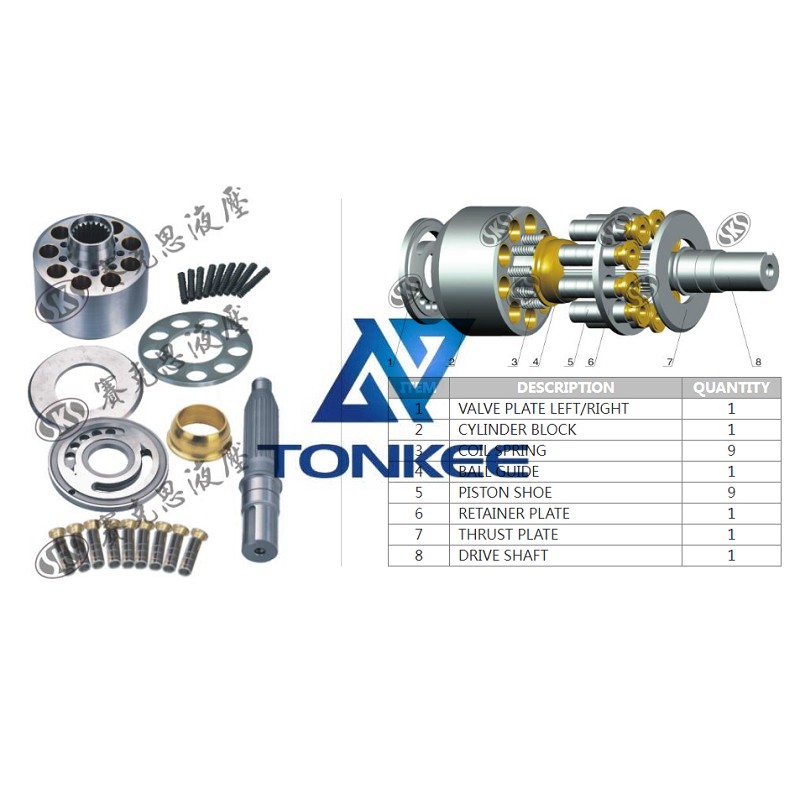

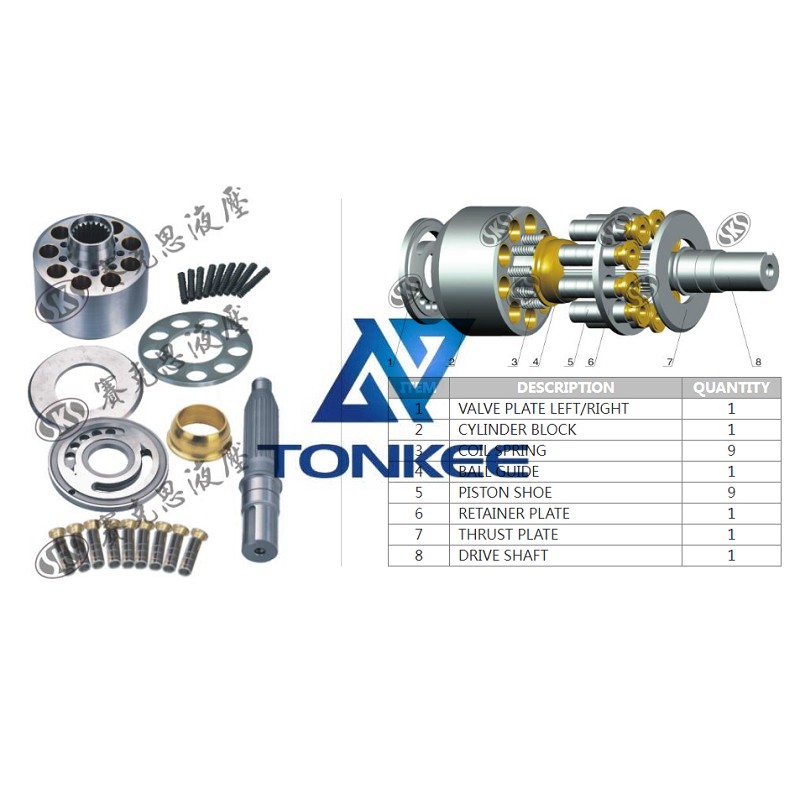

It consists of several key components, including a housing, an input shaft, a rotating group, a valve plate, and a thrust plate. These elements work together to ensure the smooth and reliable functioning of the pump.

The housing provides a sturdy enclosure for the internal components and helps maintain the structural integrity of the pump. It is designed to withstand high pressures and protect the internal mechanisms from external elements.

The input shaft serves as the driving force for the pump and is connected to a power source, such as an engine or an electric motor. As the input shaft rotates, it transmits torque to the rotating group, which consists of an eccentric ring and a series of pistons or rollers. The eccentric motion of the ring creates a reciprocating action, causing the pistons or rollers to move in and out.

The valve plate acts as a control mechanism, directing the flow of hydraulic fluid into and out of the pumping chambers. It contains a series of precision-designed ports and channels that ensure proper fluid distribution and prevent leakage.

The thrust plate is a critical component that helps maintain the axial stability of the rotating group. It provides support and absorbs axial loads generated during operation, ensuring smooth and efficient performance. The design and material of the thrust plate are carefully selected to withstand high pressures and minimize wear and tear.

The MKV33 Thrust Plate hydraulic pump by Tonkee® is known for its excellent reliability and durability.

It undergoes rigorous testing and quality control processes to ensure that it meets the highest industry standards. The pump is designed to handle a wide range of hydraulic fluids, making it suitable for various applications across different industries, including construction, agriculture, mining, and more.

When installing the MKV33 Thrust Plate pump, it is essential to follow the manufacturer's instructions and guidelines to ensure proper alignment and connection with the hydraulic system. Regular maintenance and inspection are also crucial to identify and address any potential issues before they escalate.

English

English Türkçe

Türkçe