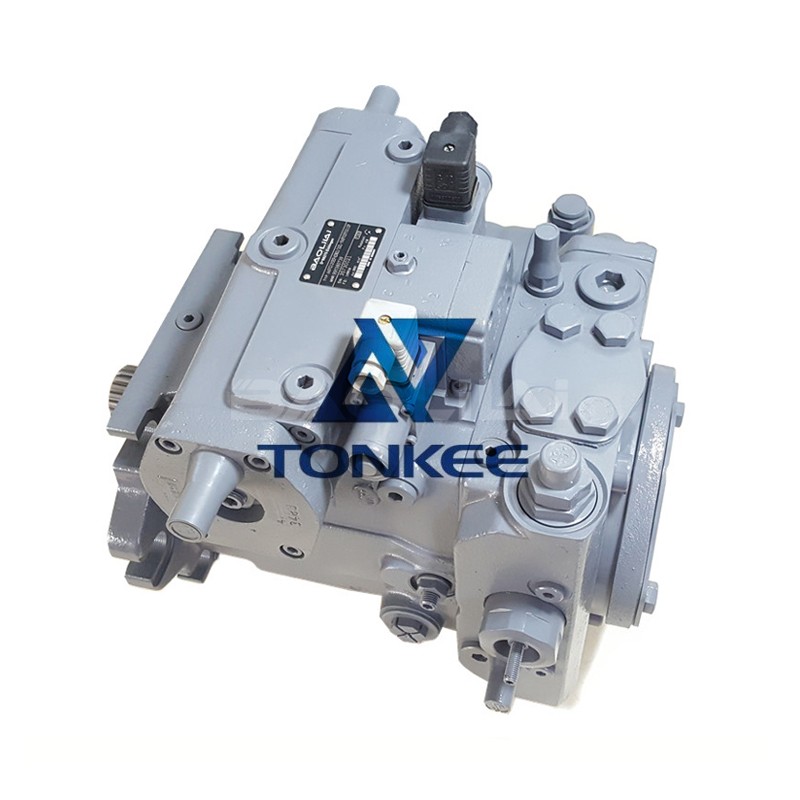

Pump Housing: The pump housing is a critical component that houses the internal parts of the hydraulic pump.

It is typically made of high-strength materials such as cast iron or steel to withstand high pressures and provide durability. The replacement pump housing should match the original specifications, including dimensions, mounting flanges, and port sizes.

Cylinder Block: The cylinder block is another vital component of the hydraulic pump, responsible for generating the pumping action. It consists of pistons and cylinder bores that create the pressure required for fluid movement. When replacing the cylinder block, it is crucial to ensure compatibility with the A4VG series model and the required displacement volume.

Pistons and Piston Rings: Pistons play a crucial role in converting mechanical power into hydraulic energy. They move within the cylinder block, generating pressure to push the fluid. Replacement pistons should have the same dimensions, surface finish, and materials as the original ones to ensure proper sealing and minimize wear.

Valve Plate: The valve plate is responsible for controlling the flow of hydraulic fluid within the pump. It consists of various control valves, such as the main pressure relief valve and the suction and delivery valves. Replacement valve plates should match the original design, including the valve configuration, pressure rating, and port connections.

Bearings and Seals: Bearings support the rotating components of the hydraulic pump, such as the drive shaft, ensuring smooth operation and minimizing friction. Seals, on the other hand, prevent fluid leakage and maintain system efficiency. Replacement bearings and seals should have the same dimensions, material specifications, and sealing properties as the original parts.

Drive Shaft: The drive shaft transfers mechanical power from an external source, such as an engine or electric motor, to the hydraulic pump. Replacement drive shafts should be compatible in terms of dimensions, spline configuration, and load-bearing capacity.

Shaft Seals: Shaft seals prevent fluid leakage along the drive shaft.

They are critical for maintaining the pump's efficiency and preventing contamination of the hydraulic fluid. Replacement shaft seals should match the original specifications, including dimensions, material composition, and sealing characteristics.

O-rings and Gaskets: O-rings and gaskets are used for sealing various connections within the hydraulic pump. They ensure airtight and leak-free operation. Replacement O-rings and gaskets should be made of compatible materials and have the same dimensions and sealing properties as the original parts.

Filtration Elements: Filtration elements are essential for maintaining the cleanliness of the hydraulic fluid and preventing damage to the pump's internal components. Replacement filtration elements should have the same filtration rating and dimensions to ensure proper fluid filtration.

English

English Türkçe

Türkçe