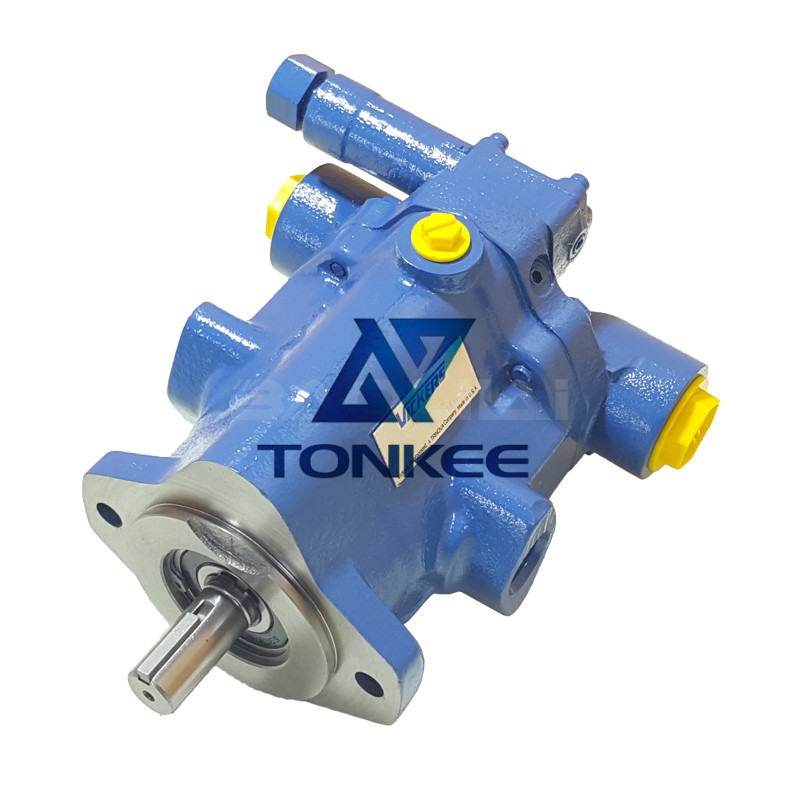

The new specification of the Vickers PVQ series hydraulic pump incorporates several advancements to optimize its performance.

Firstly, it utilizes state-of-the-art materials and manufacturing techniques, ensuring superior durability and longevity. The pump is designed to withstand harsh operating conditions, including high pressures and extreme temperatures, making it suitable for demanding industrial environments.

One of the standout features of the new specification is its enhanced efficiency. The pump is designed to minimize energy loss and maximize output, resulting in improved overall system efficiency. This not only reduces operational costs but also contributes to environmental sustainability by reducing energy consumption.

Furthermore, the new specification of the Vickers PVQ series hydraulic pump offers improved controllability and precision. It incorporates advanced control mechanisms and sophisticated hydraulic systems, allowing for precise control of flow rates and pressures. This enables operators to achieve accurate and consistent performance, enhancing the overall productivity of the system.

In terms of maintenance and serviceability, the new specification of the Vickers PVQ series hydraulic pump has been designed with ease of use in mind. It features simplified maintenance procedures and improved accessibility to critical components, reducing downtime and enhancing the efficiency of maintenance operations. This ensures that the pump can be serviced quickly and efficiently, minimizing the impact on production schedules.

Additionally, the new specification of the Vickers PVQ series hydraulic pump offers versatility and adaptability.

It can be easily integrated into existing hydraulic systems, making it an ideal choice for retrofitting or upgrading older machinery. The pump is also compatible with various control options, allowing for seamless integration into different automation systems.

Another significant benefit of the new specification is its advanced monitoring and diagnostics capabilities. The pump incorporates intelligent sensors and monitoring systems that provide real-time data on operating conditions and performance parameters. This enables operators to proactively identify potential issues, optimize system performance, and prevent costly breakdowns.

English

English Türkçe

Türkçe